Why Ricron

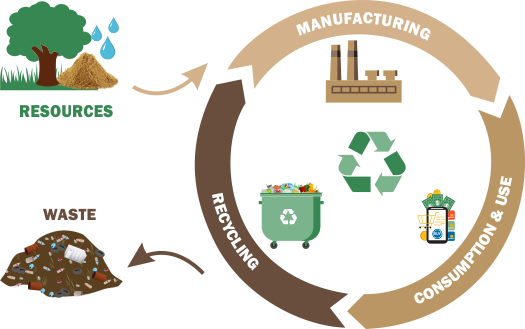

Need For Circular Economy

The world’s population is expected to peak at 10bn in 2050. Our resources, the earth’s raw materials, are not limitless. As a result, global labour and raw material costs are on the increase.

Circular economy business opportunities can offer new ways to mitigate these risks. In a circular economy, products and materials keep circulating in a high value state of use, through supply chains, for as long as possible.

Products are designed and built so that they are part of a value network where reuse and refurbishment on product, component and material level assures continuous (re-)exploitation of resources.

Problem Of Deforestation

Currently, ~40% of plastic waste in India ends up being uncollected for recycling. Proper management of this waste can create ~14 lakhs jobs and could potentially represent a ~$2bn opportunity. Circular Economy seeks to eliminate any kind of underutilization of resources or assets.

Population to reach by

2050

Land in india is

forested

Land destroyed due to

building activities

Reduction in net forest

cover in 2018

Problem Of Plastic Waste Management

India consumes an estimated 16.5 million tonnes, about 1.6 million truckfulls, of plastic annually, as per this June 2018 report in Down to Earth that cites data provided by PlastIndia Foundation, a conglomeration of associations and institutions that deal in plastic. Of this, 43 percent is plastic manufactured for single-use packaging material that will mostly find its way into garbage bins.

In all, 80 percent of total plastic produced in India is discarded. It mostly ends up choking landfills, drains and rivers and flows into the sea where it is ingested by marine animals. It leaches into soil and water, contaminating the natural environment with poisonous dioxins. At least 40 percent of the plastic waste generated every day--25,940 tonnes or about 2,594 truckload goes uncollected.

Hazards of MLP waste

Multi-layered plastics are made up of a layered composition of various types of plastics. This is a commonly used method because of the properties that the thus composed material acquires. Sometimes, the plastics material is also combined with non-plastics such as aluminium foil. Neither multi-layered plastics products made up of only plastics nor those made up in combination with a non-plastics material can be recycled.

-

Plastic contributes to greenhouse gas emission

Plastic contributes to greenhouse gas emissions at every stage of its lifecycle, from its production to its refining and the way it is managed as a waste product. It means that by 2050 plastic will be responsible for up to 13% of the total “carbon budget” – equivalent to 615 coal-fired power plants

-

MLP is not recyclable

Throwaway plastic packaging makes up 40% of the demand for plastic, fuelling a boom in production from 2m tonnes in the 1950s to 380m tonnes in 2015. By the end of 2015, 8.3bn metric tonnes of plastic had been produced – two-thirds of which has been released into the environment and remains there.

-

Statistics

Forty per cent of plastic packaging waste is disposed of at sanitary landfills, 14% goes to incineration facilities and 14% is collected for recycling. Incineration creates the most CO2 emissions among the plastic waste management methods

Benefits of Ricron

We at Ricron are able to contribute to the problem of handling waste that has no means of recycling and converting them to useful products that can be used as a substitute to wood based products. We use propitiatory technology that allows us to convert this waste into forms of sheets that are used as a building material. Hence our conversion of this waste is 100% with minimum usage of energy and without any harmful impact to the environment.

Zero Discharge Unit

We are a proud recipient of the Green Pro Certification Award, presented to us by the Confederation of Indian Industry. We use MLP waste which is non recyclable and convert this waste into useful building material products. We do not produce any waste.

Ricron Vs Plywood

- Neither Decays nor Corrodes

- Does not warp or splinter

- Compliments Veneer, ACP, Form Board

- Compliments Paint and Glue easily

- Smooth Glossy surface texture

- Very high nail and screw holding strength

| Properties | Plywood | Ricron Panel |

|---|---|---|

| Water Absorption | 8.0-12.0% | 0.25% |

| 100% Recyclable | NO | YES |

| Acid Proof | NO | YES |

| Fire Resistant | NO | YES |

| Termite Proof | NO | YES |

| Density | 0.79 gm/cm³ | 1.06 gm/cm³ |

| Compressive Strength | 32.28 N/mm² | 39.12 N/mm² |

| Water Absorbtion | 8 – 12 % | 0.25 % |

| Nail Holding Strength | Poor | Excellent |